Fabric Backed Sheet

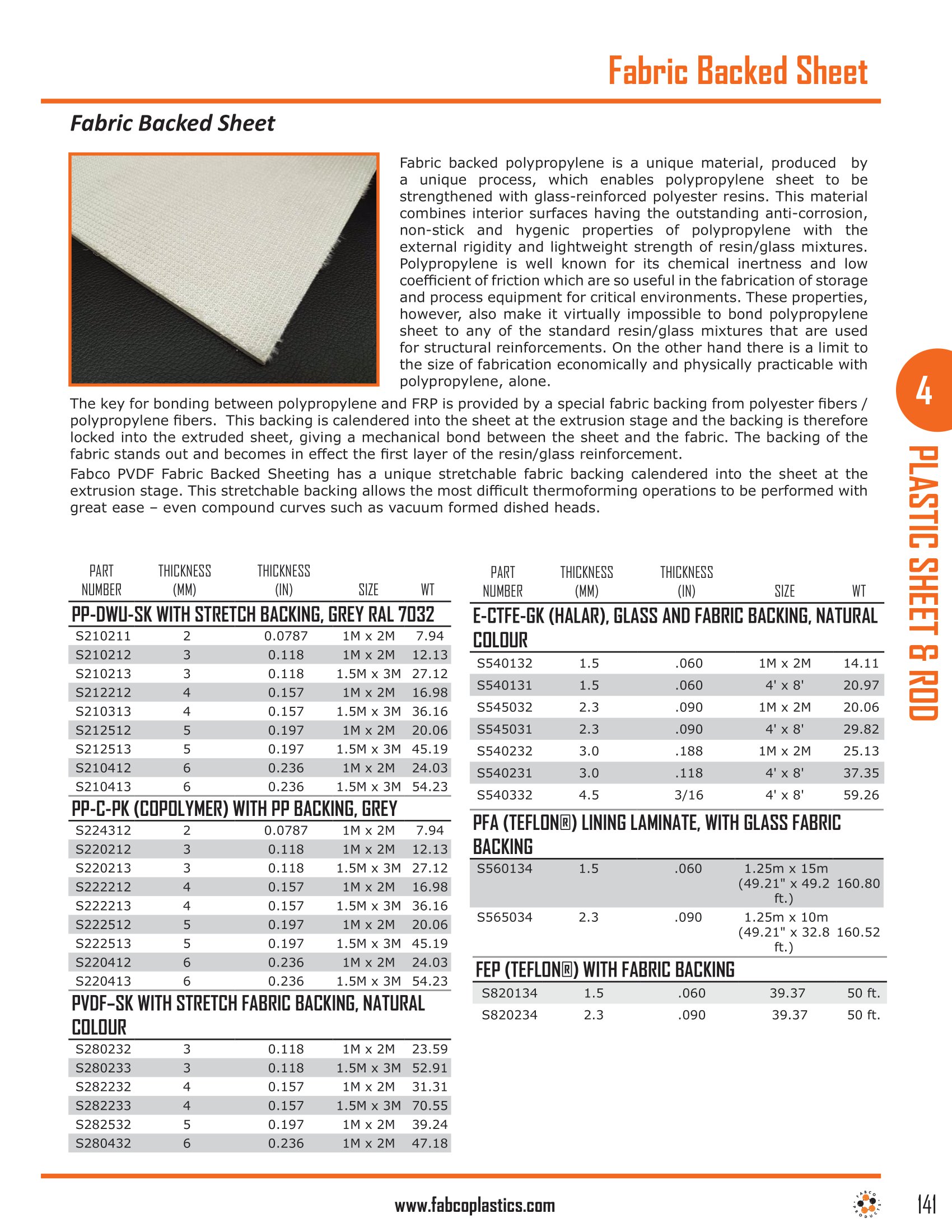

Fabric backed polypropylene is a unique material, produced by a unique process, which enables polypropylene sheet to be strengthened with glass-reinforced polyester resins. This material combines interior surfaces having the outstanding anti corrosion, non-stick and hygenic properties of polypropylene with the external rigidity and lightweight strength of resin/glass mixtures. Polypropylene is well known for its chemical inertness and low coefficient of friction which are so useful in the fabrication of storage and process equipment for critical environments. These properties, however, also make it virtually impossible to bond polypropylene sheet to any of the standard resin/glass mixtures that are used for structural reinforcements. On the other hand there is a limit to the size of fabrication economically and physically practicable with polypropylene, alone.

The key for bonding between polypropylene and FRP is provided by a special fabric backing from polyester fibers / polypropylene fibers. This backing is calendered into the sheet at the extrusion stage and the backing is therefore locked into the extruded sheet, giving a mechanical bond between the sheet and the fabric. The backing of the fabric stands out and becomes in effect the first layer of the resin/glass reinforcement.

Fabco PVDF Fabric Backed Sheeting has a unique stretchable fabric backing calendered into the sheet at the extrusion stage. This stretchable backing allows the most difficult thermoforming operations to be performed with great ease - even compound curves such as vacuum formed dished heads.

Products

- Plastic Sheet and Rod

- PVC Sheet Type 1

- PVC Sheet Type II

- PVC Clear Sheet

- Perforated Sheet & PVDF Sheet

- CPVC Sheet

- Homopolymer PP Sheet

- Copolymer PP Sheet

- HDPE Sheet

- UHMW Sheet

- Acrylic/Lexan Sheet

- Fabric Backed Sheet

- PVC Strips and Sheet

- Plastic Rod

- PVC and CPVC Shapes

- Orthotics and Prosthetics Sheet

- Round Welding Rod

- Rod, Nuts, Bolts & Washers